Work together to complete the compression bushing process for the corbel of Shenzhen Metro Line 7

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-09-29

- Views:0

(Summary description)

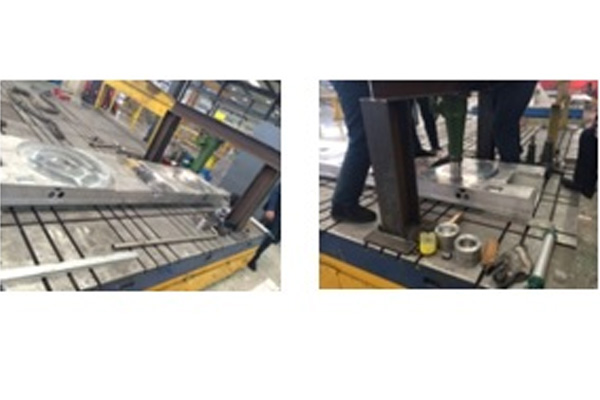

At the beginning of 2017, with the active cooperation of the production department and the tooling group, the technical department successfully completed the corbel compression bushing tooling for Shenzhen Metro Line 7. In order to meet the verticality of the bushing 0.4 and the dimensional tolerance of 0.05, a mechanical jack was used as an auxiliary device, and the bush was placed in liquid nitrogen for cooling. Through the guiding action of the auxiliary components, and the jack as the positioning reference, the pillow was successfully completed. The pressing process of beams has been completed for 1 column, 12 corbels and 24 corbels. No unqualified parts have been produced, and an important technological breakthrough has been completed. This tooling is after the traction beam. For a breakthrough in important large components, our company has the ability to independently produce corbels

Work together to complete the compression bushing process for the corbel of Shenzhen Metro Line 7

(Summary description)

At the beginning of 2017, with the active cooperation of the production department and the tooling group, the technical department successfully completed the corbel compression bushing tooling for Shenzhen Metro Line 7. In order to meet the verticality of the bushing 0.4 and the dimensional tolerance of 0.05, a mechanical jack was used as an auxiliary device, and the bush was placed in liquid nitrogen for cooling. Through the guiding action of the auxiliary components, and the jack as the positioning reference, the pillow was successfully completed. The pressing process of beams has been completed for 1 column, 12 corbels and 24 corbels. No unqualified parts have been produced, and an important technological breakthrough has been completed. This tooling is after the traction beam. For a breakthrough in important large components, our company has the ability to independently produce corbels

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-09-29

- Views:0

At the beginning of 2017, with the active cooperation of the production department and the tooling group, the technical department successfully completed the corbel compression bushing tooling for Shenzhen Metro Line 7. In order to meet the verticality of the bushing 0.4 and the dimensional tolerance of 0.05, a mechanical jack was used as an auxiliary device, and the bush was placed in liquid nitrogen for cooling. Through the guiding action of the auxiliary components, and the jack as the positioning reference, the pillow was successfully completed. The pressing process of beams has been completed for 1 column, 12 corbels and 24 corbels. No unqualified parts have been produced, and an important technological breakthrough has been completed. This tooling is after the traction beam. For a breakthrough in important large components, our company has the ability to independently produce corbels

Scan the QR code to read on your phone

Related News

Contact information

Address:

No. 0001, Jingkai Street, the intersection of Jingkai Street and Dongsheng Road, Gongzhuling Economic Development Zone, Jilin Province

Tel:0434-6075207

Post Code:136105

Quick Navigation

Mobile

Online message

All rights reserved:Jilin Red Star Railway Vehicle Equipment Co.Ltd 吉ICP备14005990号 by:300.cn